Dynamic Rigs

Overview

To avoid failures during engine test stand or flight testing, spin testing of new parts and components must begin early in a jet engine development program. For customers who choose to perform testing operations in-house, Test Devices offers the next generation of spin testing equipment. Our exclusive Dynamic Spin Rig™ more closely duplicates the reality of an operating jet engine. Advanced mechanical, thermal, material utilization, and vibration stress tests can be performed with one machine that more fully accounts for conditions experienced by the real-world component. As a result, test data is much more robust and relevant than can be achieved using conventional spin test equipment.

Why It Matters

The cost of finding design problems late in development or during fielding can be high in risk to personnel, wasted dollars and missed deadlines. Component testing early and often is safer and less expensive in the long run.

Standard spin rigs are designed to test disks, but they do not have the capability to test blades and dampers; those must be tested on a shaker table. Resonance in a Blisk/IBR is highly influenced by the total component, so testing a segment on a shaker table gives limited results at best. IBR/Blisk tuning and repair can cause different blades to vibrate with different – perhaps catastrophic – mode shapes. Validation is essential before fielding components.

What You Can Do

Test Devices’ Dynamic Spin Rig enables disks to be tested in real time, with the blades installed. Components are tested under centrifugal load, at operational speeds, with realistic temperature gradients, and with representative HCF engine orders and mode shapes. Resonance can be held at speed to gather realistic data. Other component parameters, such as stresses and elastic/plastic radial growth, can be measured in real time. Such advanced capabilities help to reduce engineering redesigns, lower the risk of in-service component failure, speed project completion, and reduce total cost.

Dynamic Spin Rigs are also capable of performing conventional spin tests such as overspeed, burst and low cycle fatigue (LCF) tests, as well as Advanced Spin Testing™ and Dynamic Spin Testing (high cycle fatigue – HCF) protocols.

Significantly, the ability to test disks with the blades installed and under centrifugal load is unique to Test Devices, and only Test Devices offers all of these capabilities in one system.

Dynamic Spin Rig Capabilities Include

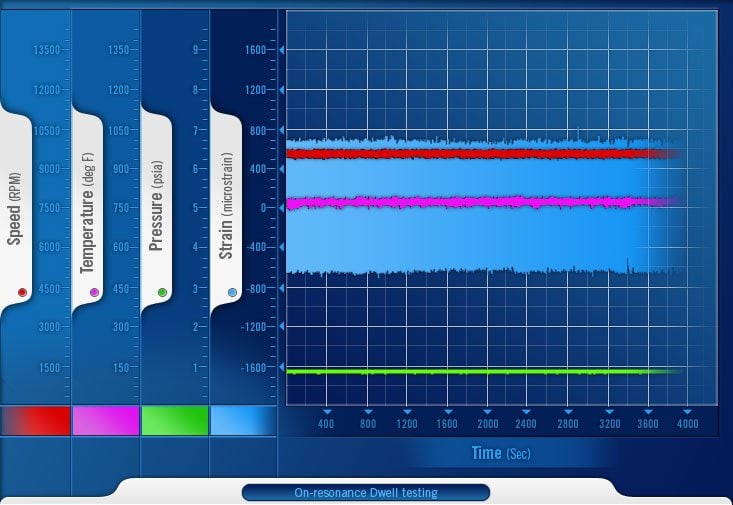

- Precise speed control to allow for “on resonance” dwelling in order to accumulate HCF cycles and evaluate the life of blades under realistic operating conditions.

- Elevated temperature testing with axial and radial thermal gradients accounts for both mechanical and thermal stresses. This leads to more accurate prediction of component hot spots.

- Extremely safe containment developed from burst testing high energy rotors, such as fully assembled turbine rotors.

- Detection of cracks in rotating assemblies with a patented system that automatically shuts down a test when a crack has been detected, saving the flawed component for analysis.

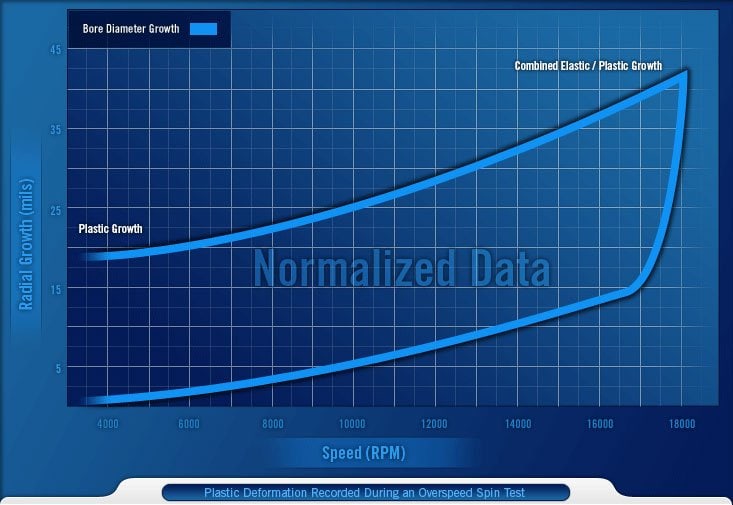

- Measurement of the growth of components at speed to allow for correlation with elastic/plastic material models.

- Excitation of resonant vibrations in bladed rotors to evaluate blade/damper design performance and HCF life by simulating excitation force imparted by engine stators.

Blade Testing

Managing resonant vibration of bladed jet engine rotors represents a technical challenge for engine programs. During operation, engine blades are subjected to bending and twisting modes, caused by resonant vibration, resulting in blade failure in extreme cases. To address this issue, blade, disk and stator geometry can be modified, and dampers introduced to minimize vibration amplitudes.

Dynamic Spin Rigs simulate engine dynamic loads (centrifugal stress), thermal stresses (elevated temperature thermal gradients) and excitation forces. During testing, blades and dampers undergo actual centrifugal stress at operational speeds, replicating operational component loads. Thermal gradients can also be applied in order to test at engine operating temperatures and thermal stresses. The excitation force used to produce resonant blade vibrations simulates the impact force resulting from blade/stator passage, causing blade distortion. Both high frequency flexural and torsional modes can also be excited with engine orders (EO) of up to 100.

Dynamic Spin Rigs can carry out the following tests to evaluate the performance of complete blade/damper/rotor stage assemblies.

Damper Evaluation

Dynamic Spin Rigs provide a convenient way to evaluate the performance of damper designs installed in “engine ready” hardware. Complete rotors can be assembled with dampers installed and blade resonant vibrations excited for critical modes to determine the effect of various damper designs on vibration amplitudes. Dynamic Spin Rigs are very flexible and several different damper designs or EO configurations can be tested during the same day, with little down time between tests.

High Cycle Fatigue

Speed can be held at resonance for long periods of time and blade cracking can be detected to measure time to crack. Resonance dwell testing is important for measuring the reduction in fatigue life that results from various kinds of blade damage from foreign object impacts.

Blade Characterization

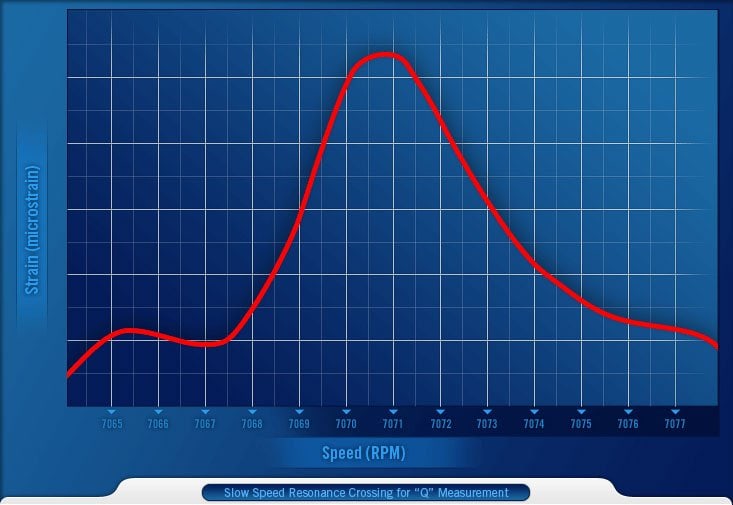

Characterization of the resonant vibration modes and amplitudes of engine blades is critical for design optimization. Slow resonance crossing enables calculation of blade amplification factors for measuring the severity of various modes and the risk they present.

Advanced Spin™ Testing

Advanced Spin Testing incorporates non-traditional tests that either include variation of standard test parameters or provide additional data. Dynamic Spin Rigs can run advanced spin tests, including Radial Growth Testing and Thermal Gradient Testing.

Radial Growth Testing

Dynamic Spin Rigs can measure the diametrical or radial growth of high-speed rotating components in real time. Because the centrifugal forces on rotating components grow alarmingly fast as rotational speeds increase, measuring the growth at speed can be very valuable. Test Devices has used its radial growth testing during several Federal Aviation Administration overspeed/burst certification tests with great success. Growth data taken at the speed at which a component goes plastic can be very important for 3D model verification.

Thermal Gradient Testing

Dynamic Spin Rigs provide a thermal environment that more accurately simulates the engine stress environment by including both the mechanical (centrifugal) and thermal stresses. Traditional spin rigs only provide for component testing at either ambient or isothermal elevated temperatures. While isothermal elevated temperatures add an additional thermal stress component to the mechanical stress (centrifugal force), they do not apply the correct stress field across the component. Test Devices’ Dynamic Spin Rigs can perform overspeed, burst and LCF testing with radial and axial temperature gradients.

Standard Spin Testing

Standard Spin Testing equipment typically performs overspeed, burst and low cycle farigue testing. Dynamic Spin Rigs can provide additional valuable test data from these routine test protocols.

Overspeed Burst Testing

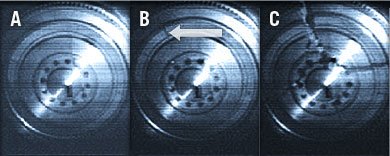

Figure 6 – Diesel flywheel burst daptured with high-speed video (A: Test article during normal spin, B: Initial crack formation, C: Test article burst)

Dynamic Spin Rigs allow for the capture of valuable test data from burst events by recording with high-speed camera equipment. The safety view ports installed on the bottom of the machine provide a clear view for the high-speed camera, mounted underneath the test chamber, a clear view of the complete rotating assembly.

Low Cycle Fatigue (LCF) Testing

Test Devices spin test systems have long been recognized for their ability to perform rapid cycling with high power density drives, resulting in shorter schedules for LCF testing programs. Dynamic Spin Rigs include this capability as well as the ability to simulate mission profiles by dwelling at multiple speeds, for set periods of time, during a single cycle. Additionally, the Dynamic Spin Rig includes very accurate speed control to satisfy tightly toleranced speed requirements.

Crack Detection

A cracked rotor, with pristine crack surfaces, is much more valuable for analysis purposes than component shrapnel which have impacted the spin chamber containment. Because of the advantage of preserving cracked test components, each Dynamic Spin Rig includes Test Devices’ patented crack detection monitoring system. The system compares the change in the vibration vector for each cycle to all of the previous completed cycles, in order to detect the initiation and growth of cracks. Test Devices has halted many LCF tests prior to component failure due to cracks detected by this unique system, and preserved numerous customer components.

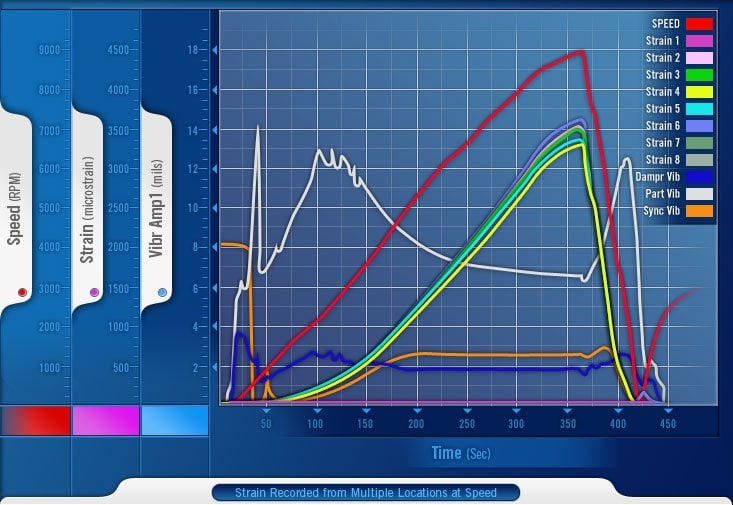

Strain Survey

Test data recorded during strain survey spin testing is often used to correlate 3D design models. Strain gauges mounted to the rotating assembly, in areas of peak stress, record strain throughout the spin test, up to component failure. Information gathered in these tests can be used to test complex parts, understand assembly stresses and determine the properties of materials (including composites) when exposed to operational strain under realistic conditions.

High-Speed Balancing

When balancing a rotating assembly on a standard balance machine becomes impractical, or when high-speed balancing is required, Dynamic Spin Rigs allow the operator to precisely measure the unbalance of the rotating assembly at speed in the spin chamber. Test Devices often uses its high-speed balancing system to precisely balance large, complex test components prior to carrying out spin test protocols. Rather than having large bladed rotor assemblies rotating at high speed on standard balance equipment on the shop floor, the rotor is safely contained within the robust spin chamber of a Dynamic Spin Rig.