A Comprehensive Guide on CNC Machining

Computer numerical control (CNC) machining has proven itself an ideal method for mass producing metal and plastic parts. Even as other manufacturing methods like 3D printing have gained prominence in recent years, CNC machining has remained one of the most popular choices for a wide variety of fabrication needs. The aerospace sector relies heavily on CNC machining for the production of complex and mission-critical parts and components.

By leveraging the precision and automation of computerized control, CNC machining allows for the creation of intricate and accurate designs. In the past, manual machining processes relied on highly trained and skilled human operators to control the machinery. While some machine shops still use skilled machinists for prototypes, small-volume orders, or parts where repeatability or tolerances aren’t important, CNC machining has virtually eliminated the risk of human error in many manufacturing operations. Advanced programming regulates precise cutting patterns to ensure part-to-part uniformity and reliable adherence to tight tolerances.

What is CNC Machining?

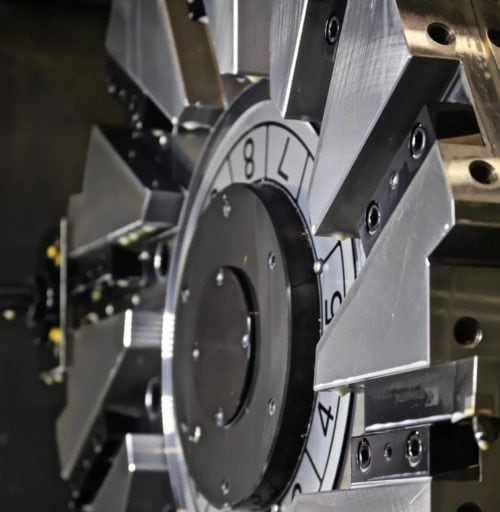

CNC machining is a modern manufacturing process that takes in specific programmed instructions and uses that information to direct tooling as it cuts into the workpiece. CNC machining is not limited to one tool or piece of machinery. A spindle holds numerous tools, and CNC machines can often use multiple tools simultaneously from different angles. The term “numerical control” simply refers to the automated control of a machining process. The most common computer language for CNC machines is called G-code, though another language known as M-code is also sometimes used.

How Does CNC Machining Work?

To use a CNC machine, a skilled professional must program the computer. Once the machine has been activated, it reads through the program and enacts each of the instructions, employing a variety of tools and fabrication processes along the way. The CNC machine will follow its program under the assumption that all tools have carried out their function flawlessly. Small mechanical margins of error still exist, especially when the CNC process involves simultaneous cuts or other complex instructions. By and large, however, well-maintained CNC machines reliably perform in accordance with their programming.

While numerical control machines of the past read instructions through punch cards, today’s CNC machines require advanced computer programming. Operators enter the instructions into a computer and save the file into the machine’s records, where it can then easily find and invoke the instructions over and over. While many technicians are familiar with G-code and M-code languages, machine shops most commonly use computer-aided manufacturing (CAM) software, which can turn a computer-aided design (CAD) drawing into usable instructions for CNC machinery. This type of software makes the operator’s job much easier.

What are the Common Types of CNC Machines?

Numerous types of CNC machinery exist, enabling machine shops and manufacturers to conduct an expansive range of automated machining processes. Some of the most common CNC machine types include:

- CNC mills. CNC milling machines can cut a wide variety of materials in multiple dimensions. Most milling machines include an X, Y, and Z axis, which allows for exceptional detail and complexity. Cutting-edge machines may include additional axes for further precision and detail.

- CNC turning centers/CNC lathes. These specialized manufacturing tools are ideal for creating parts with symmetry around a central axis, such as pipes and shafts. CNC technology gives lathes an added level of precision that can be used to create more intricate parts.

- Plasma cutters. Plasma cutters seamlessly slice through material by using electricity and compressed-air gas to form a plasma torch. Plasma cutting requires conductive material, so it is mostly used to cut conductive metals such as steel, copper, brass, or aluminum.

- Water jet cutters. Water jet cutters create an intense stream of water that cuts through tough materials. Adding abrasives to the water stream facilities cutting of harder materials, such granite and titanium.

What are Some Popular Machining Techniques?

With many CNC machining processes available, it can be difficult to determine which ones to use for a specific project. While there is some overlap, most machining methods lend themselves to specific project or design needs. Here are some of the most popular and versatile CNC machining techniques:

- Roughing and semi-finish machining. These processes get most of the way to the final product, while leaving some excess material on the outside for fine-tuning by more precise machinery. Semi-finish machining reveals the final part geometry, but only strips the material within about 0.05” of the target dimensions. Also called roughing or rough machining, this process often uses CNC machinery to produce high volumes of roughed parts ready for final machining.

- Turning. Turning is one of the oldest manufacturing processes, but modern CNC lathes use advanced tooling and precision control to create highly accurate cylindrical parts with numerous features. As the workpiece rotates at high speeds, cutting tools move along the length of the piece to cut away material. More advanced turning centers can conduct additional processes, such as drilling holes.

- Milling. Milling holds the piece steady while a spindle with various cutting tools rotates around it, making precise cuts in accordance with the programmed instructions. Although the workpiece is mainly held horizontally, the cutting tool functions in the X, Y and Z directions. Four-axis and five-axis CNC milling machines have become increasingly common in recent years, offering further precision, speed, and complexity.

- Solid Sink EDM. Unlike the other processes, which all involve direct contact between tools and the target surface, solid sink electro-discharge machining (EDM) uses a an electrode that releases a powerful discharge that forces material to strip away from the metal surface. The material must be immersed in a dielectric fluid during the manufacturing process, and the electrode requires frequent replacement.

What are the Benefits of Machining with Test Devices?

Test Devices by SCHENCK has become a premier provider of precision machining services for aerospace OEMs. We serve a customer base that accepts nothing less than the highest levels of accuracy, quality, and compliance with industry standards. Our manufacturing operations operate in strict compliance to AS9100/ISO 9100 quality management standards.

All our customers know we can respond and adapt quickly to project changes with minimal impact on production and delivery schedules. All of our teams, including machining, spin testing, balancing, and logistics operate in unison to provide end-to-end efficiency on every project.

For more information about Test Devices by SCHENCK and our machining capabilities for the aerospace sector, please contact us today.