Machining in the Aerospace Industry

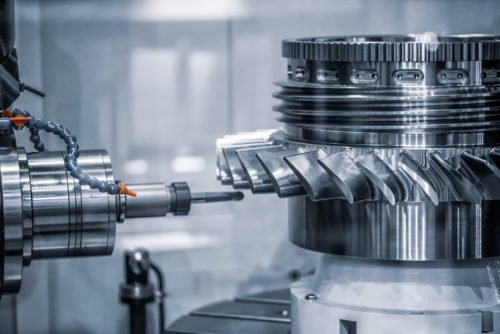

The success or failure of aerospace operations is dependent on the accuracy, precision, and quality of the components employed. For this reason, aerospace companies utilize advanced manufacturing technologies and techniques to ensure their components fully meet their needs. While new manufacturing methods such as 3D printing are quickly gaining popularity among industry professionals, traditional manufacturing methods such as machining continue to play a critical role in the production of parts and products for aerospace applications.

Recent advancements in machining techniques and technologies—such as better CAM programs, application-specific machine tools, enhanced materials and coatings, and improved chip control and vibration dampening properties—have significantly changed how aerospace companies manufacture critical aerospace components. However, sophisticated equipment alone is not enough. Manufacturers must have the expertise to overcome the challenges of machining materials for the aerospace industry.

The following blog post discusses what aerospace component machining processes encompass and what machining challenges aerospace component manufacturers face.

What Does Aerospace Component Machining Involve?

In concept, machining raw material into aerospace parts and products seems simple. However, turning materials into functional components that fully meet the specifications and standards of the application necessitates extensive engineering and operational expertise.

Aerospace manufacturers often invest in CAD/CAM software and automation components to achieve better part quality, process control, and production efficiency. However, while these cutting-edge technologies help deliver consistent and dependable output, company employees must have the proper knowledge and skills to use them to machine components effectively and efficiently.

What Are the Challenges of Machining Nickel-Based Superalloys?

Many critical aerospace components, such as hot sections of jet engines, are made from nickel-based superalloys, which are aerospace materials characterized by their ability to offer superior performance in demanding environments. This quality stems from their excellent strength at high temperature, toughness, hardness, oxidation/chemical resistance, creep resistance, and thermal insulation properties. While these properties make these materials an excellent choice for such components, they also make them difficult to machine. Some of the challenges faced by machinists working with nickel-based superalloys include:

- High cutting force requirements. The high dynamic shear strength of nickel-based superalloys necessitates the application of significant cutting forces to machine the material into the desired part or product.

- Poor thermal conductivity. Since nickel-based superalloys do not readily conduct thermal energy, the heat generated by the cutting operations migrates to the tooling rather than the chip. As a result, machine tools experience greater wear in these machining operations than the machining operations for other materials.

- Susceptibility to work hardening. Superalloys are prone to work hardening, which leads to a greater risk of notch wear.

Given the proper engineering and operational expertise, machinists should be able to overcome these challenges and produce machined components suitable for use in aerospace applications.

Why Partner With Test Devices for Your Aerospace Machining Needs?

At Test Devices (a business unit of SCHENCK USA CORP.), we’ve produced critical rotating components for customers across a wide range of industries for over 40 years. This extensive experience, combined with our full-service manufacturing capabilities (semi-finish machining, inspection, and testing all under one roof), allows us to provide expert and reliable product solutions for major aerospace propulsion suppliers, automotive manufacturers, industrial power generation manufacturers, and numerous other industrial companies.

To learn more about our products and services and how they can benefit your aerospace application, contact us today. To discuss your requirements with one of our experts, request a quote.