Fatigue Rigs

Fatigue Spin Test Rigs are designed to expose rotating components to operating loads under realistic conditions. This enables rotor manufacturers to validate the predicted life (in numbers of cycles) of designated critical rotating components.

Test Devices’ Fatigue Rigs utilize the highest productivity drive systems in the industry. Our higher power drive systems are specifically designed for Low Cycle Fatigue (LCF) testing, enabling customers to “fast cycle” their test components. Fast cycling shortens program durations, cuts costs, and reduces the risk of damaging test assets.

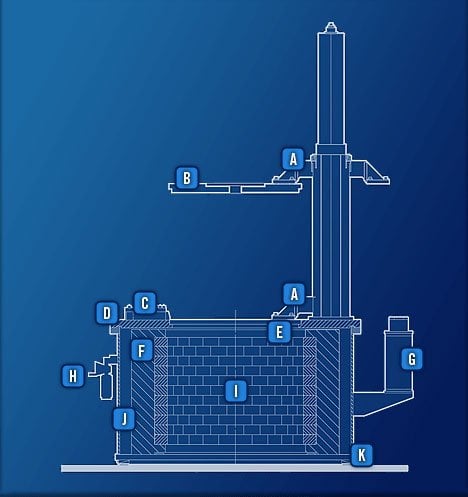

Standard Modules

Data Acquisition: All test data (e.g., temperature, speed, vibration, strain) are recorded on a custom digital data acquisition system.

Containment Chamber: Industry leading containment capability designed for high energy applications.

Vacuum System: Includes the pump/blower set, providing a vacuum level below 400 milliTorr, together with controls and level gauge.

Cyclic Controller: Provides accurate control of speed for low cycle fatigue test protocols, including complex (mission profile) cycles. See Figure 1.

Drive Systems: Test Devices offers a range of drive options for both air turbine drive systems and direct electric motor drive systems, covering the speed range up to 160,000 rpm. Our 700 Series turbines are designed specifically to perform LCF tests very rapidly, providing good data faster.

Key Features

- Lid Lift

- Lid

- Lid Dog

- Cover

- Lead Brick Retainer Ledge

- Forged Steel Armor Liner

- Air Float Counterbalance

- Air Regulator

- Lead Brick Liner

- Casing

- Leveling Wedges

Armor Cylinder – Primary Containment

A robust armor cylinder is mandatory for long-term safety of the machine and the operator. The steel armor cylinder Test Devices uses for the primary containment of an uncontrolled burst is forged and heat treated. The single piece forging eliminates welds, reducing stress concentration and strength issues. It is designed to yield only under overload conditions, with an 18% elongation.

Test Devices designs armor cylinders to be fully elastic in both shear and tension, and they are reinforced at the top and bottom by a retention ledge. This feature strengthens the ends of the cylinder and prevents the extrusion of the soft lead inner liner against the covers.

Casing

The casing is fabricated from high strength steel. It encloses the entire test chamber and sustains a vacuum using airtight seals. The inside of the casing is larger than the outside diameter of the armor cylinder to allow the inner safety liner to expand if overloaded. This extra room allows the containment cylinder to stretch and absorb energy without ruining the vacuum chamber during an exceptionally high energy burst.