Literature

Quality Control & Management of Aerospace Rotating Components

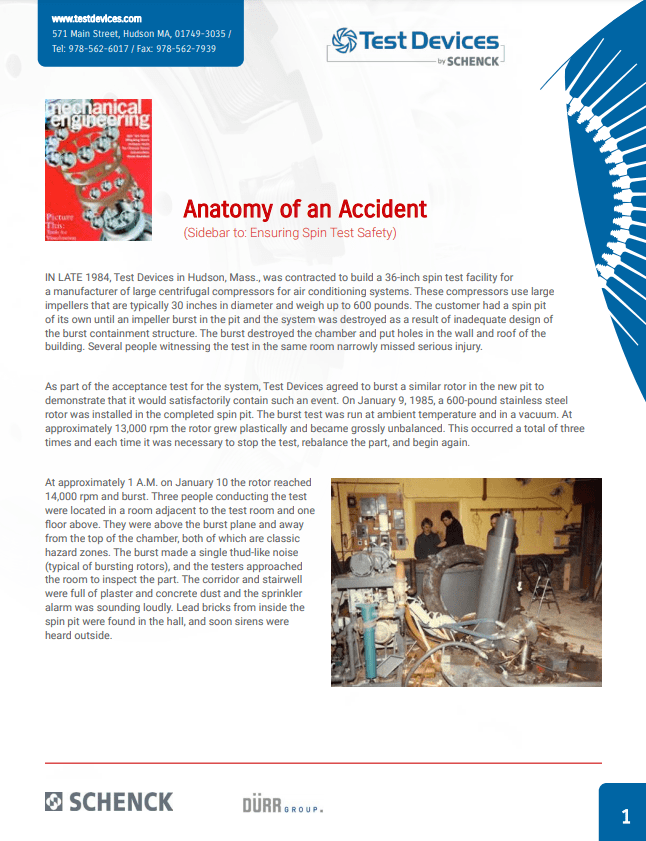

Performing effective quality control procedures is one of the most vital aspects of aerospace manufacturing. Each component must not only be precision-crafted according to rigorous specifications but also thoroughly tested to ensure durability. Without robust quality control and management systems in place, serious accidents can occur, endangering the public.

Unbalance Budget Analysis: Optimizing Rotor Design for Manufacturing Performance

Unbalance correction strategy is critical in rotor production and avoiding persistent issues in your production line. Discover how Unbalance Budget Analysis optimizes manufacturing processes & cost by streamlining the workflow and focusing on the parts which are responsible for unbalances.

Green Technology: Balancing & Spin Testing High Speed Electric Rotors

Our comprehensive ebook breaks down everything you need to know about spin testing and balancing electric rotors, as well as well as how you can get production support

Solving Noise and Vibration Issues for eVTOLS from the Source

The concept of Urban Air Mobility (UAM) is transforming into a reality as a wide range of aircraft designs and architectures are being developed for air taxis and drone delivery vehicles.

Electric Aviation and a Sustainable Future

The race to curb the emissions from aviation is on! Globally, industry leaders, start-ups, and governments have been working towards full electrification of aircraft to reduce the emissions to 50% of today’s level by 2050.

A Comprehensive Guide on E-Mobility and E-Aviation

A vital element of the effort to decrease CO2 emissions is the electrification of transportation. On-demand mobility services, connected and autonomous vehicles, and alternative powertrains have also driven increased interest in electric-powered transport

Key Benefits of a Full Service Semi-Finish Manufacturer

The following eBook outlines the qualities that make us an unparalleled industry leader in rough and semi-finish machining of rotating parts, including…

Unparalleled Value: Competitive Advantages of Working with Test Devices

At Test Devices, we’re able to combine our formidable resources with comprehensive customer service to engineer the solutions you need. In this eBook, we will provide an overview of our services, which include…

An Introduction to Dynamic Spin Testing

Dynamic Spin Rigs (DSR) include patented technology that Test Devices has been pioneering since 2004. A DSR is a spin test system that can excite blades under centrifugal loading. Our resource breaks down everything you need to know about Dynamic Spin Rig (DSR) as well as key ingredients for successful dynamic spin testing.

On Track for Growth: Why Spin Testing Matters for eDrive Systems

As the race for improved electric drives for electric vehicles, drones, and hybrid drive/ propulsion systems accelerates, the need to design rotors that exhibit the structural integrity, proper balance, and durability to tolerate high-performance applications is becoming crucial to the advancement of eDrive technologies.

High Temperature Exhaust Gas Testing

Subscale jet engine testing provides a solution to the time, monetary, and capability limitations engineers face during their engine R&D phase.

Balancing 101: What You Should Know About Balancing Your Rotating Part

Avoid taking unnecessary risks when balancing your rotating components. This everything-you-need-to-know guide walks through what you need to know about balancing your parts.

Spin Testing for Manufacturing (ebook)

Test Devices’ comprehensive ebook breaks down all important factors that need to be considered when preparing to spin test rotating components.

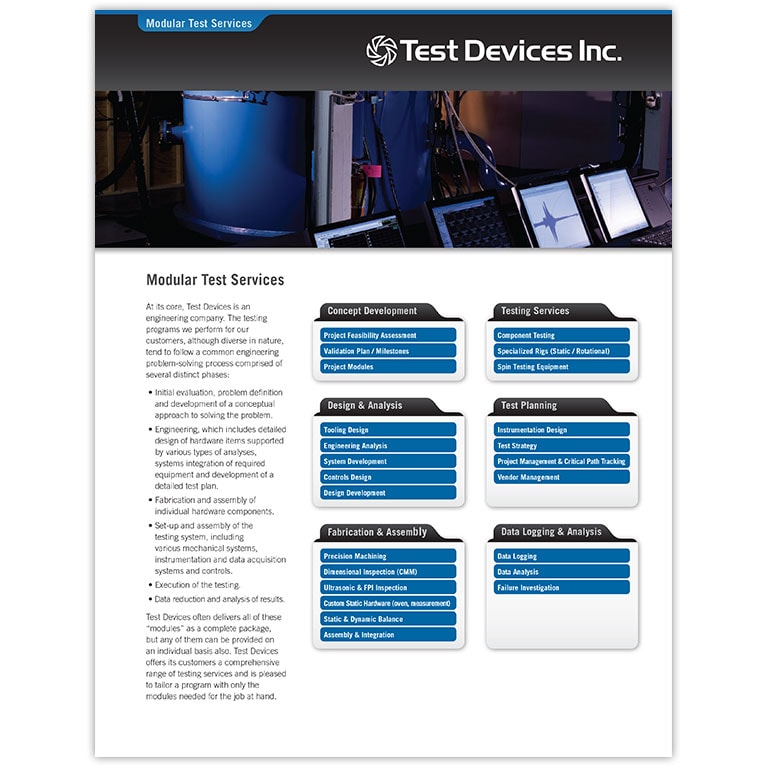

Modular Test Services

At its core, Test Devices is an engineering company. The testing programs we perform for our customers, although diverse in nature, tend to follow a common engineering problem-solving process comprised of several distinct phases.

Crack Detection Services / Low Cycle Fatigue (LCF) Testing

Test Devices’ patented Crack Detection System is a Real Time Rotor Health Monitoring System for Low Cycle Fatigue (LCF) testing.

Services

Test Devices provides rotational and other testing services and equipment to demanding markets with exacting applications and requirements.

White Papers

Real-Time Crack Detection System

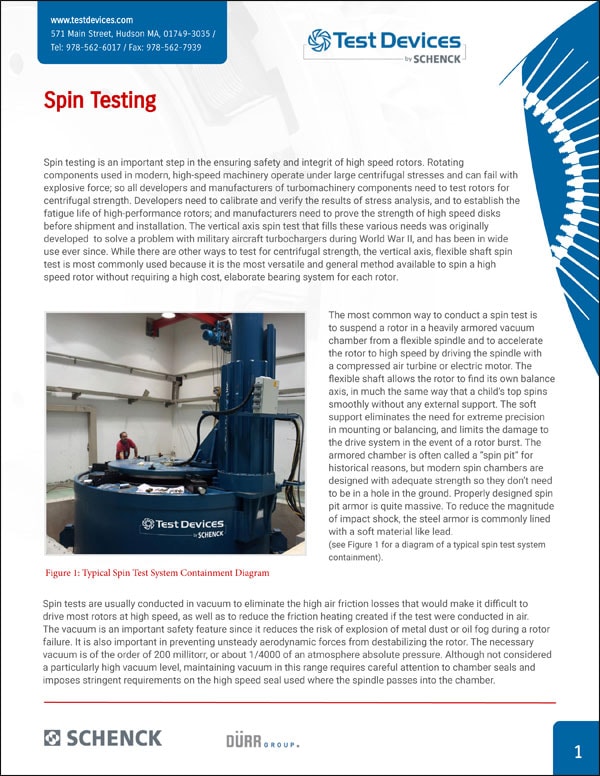

The development of jet engines and other high-speed machinery requires extensive testing to establish the integrity and useful life of high-speed rotating components. A fundamental evaluation technique for turbine engine rotors is to empirically test and validate the number of cycles the rotors can withstand, either to a predetermined number or all the way to failure. This type of test is typically referred to as a low-cycle fatigue (LCF) test.

Edrives

The need for testing the rotors for the high-speed electric motor is on the rise. The race for better electric drives for EVs, drones, hybrid drive/propulsion systems is accelerating.

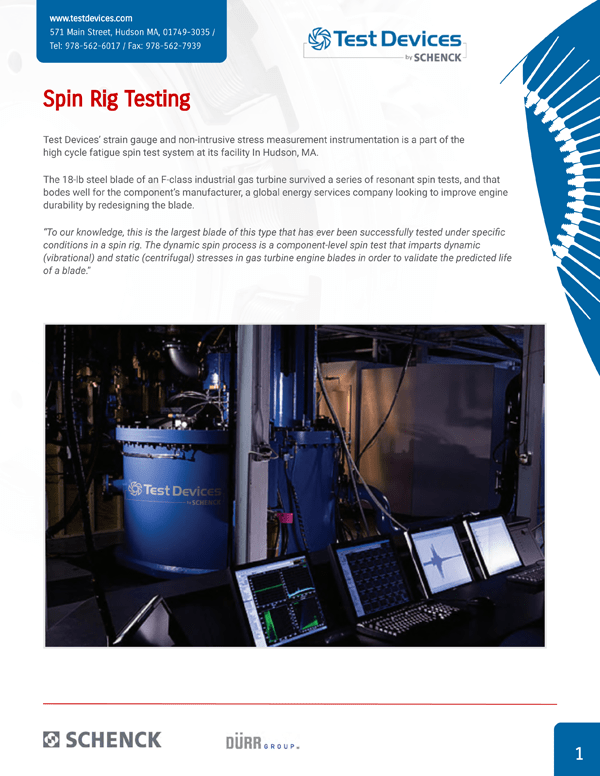

Spin Rig Testing Nets Results

The 18-lb steel blade of an F-class industrial gas turbine survived a series of resonant spin tests, and that bodes well for the component’s manufacturer, a global energy services company looking to improve engine durability by redesigning the blade.

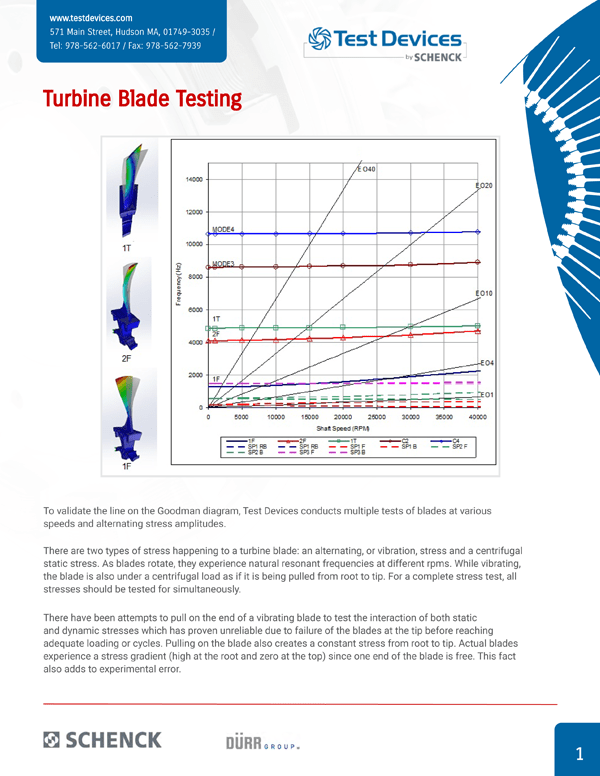

A New Spin On Turbine Blade Testing

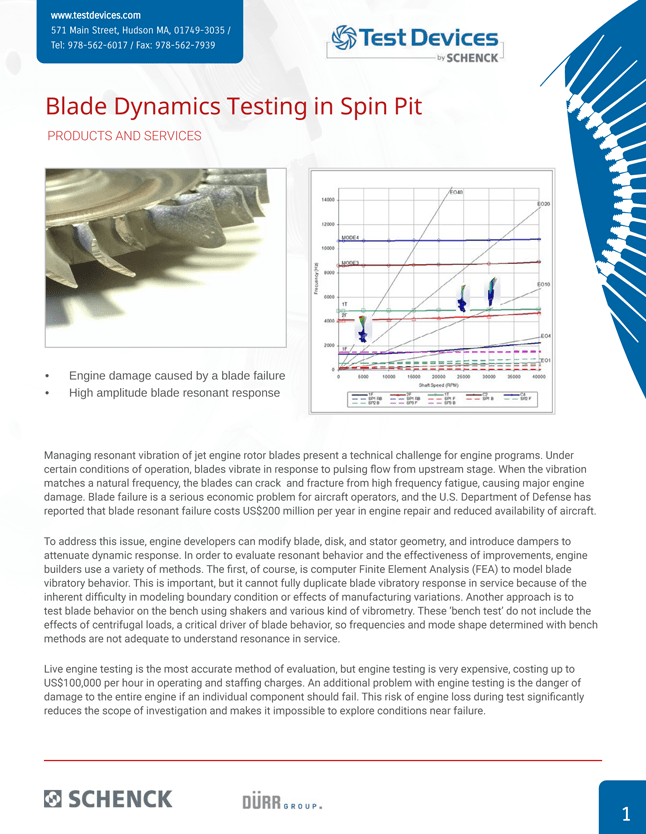

There are two types of stress happening to a turbine blade: an alternating, or vibration, stress and a centrifugal static stress. As blades rotate, they experience natural resonant frequencies at different rpms. While vibrating, the blade is also under a centrifugal load as if it is being pulled from root to tip. For a complete stress test, all stresses should be tested for simultaneously.

Advancement in Heated Spin Testing Technologies

An ever more rapidly accelerating trend toward pursuing more efficient gas turbines pushes the engines to hotter and more arduous operating conditions. This trend drives the need for new materials, coatings and associated modeling and testing techniques required to evaluate new component design in high temperature environments and complex stress conditions.

Flywheels

Researches are developing ways to ensure that power-packed flywheel-battery systems stay safely contained.

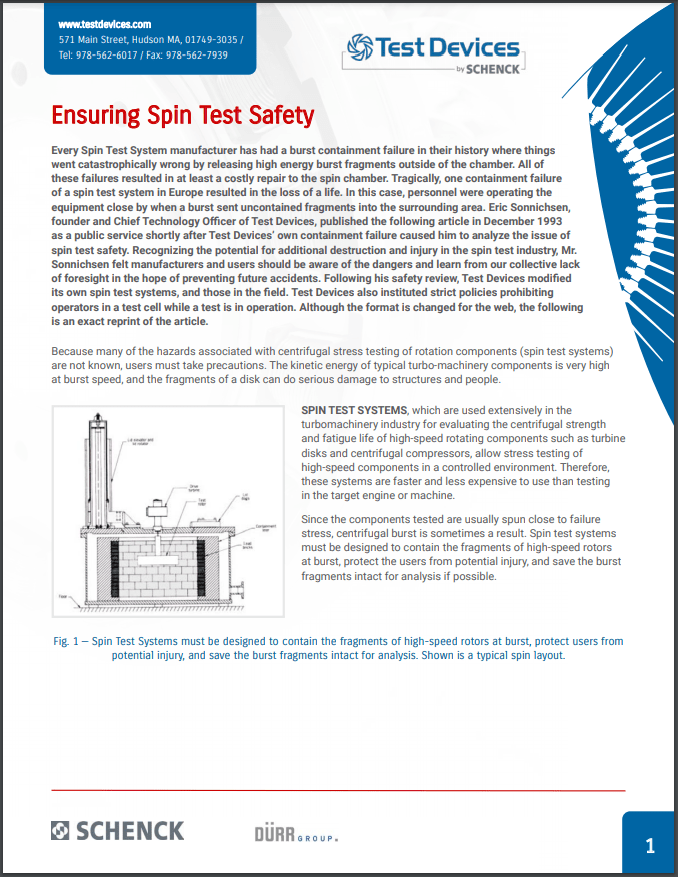

Spin Testing Systems

Allow one to understand the stresses and failure modes of high speed devices in a safe environment.

Real-time Detection of Developing Cracks in Jet Engine Rotors

Published Conference Article on Crack Detection

Thermal Mechancial Fatigue Testing

Realistic Engine Thermal and Centrifugal Stresses During a Spin Test