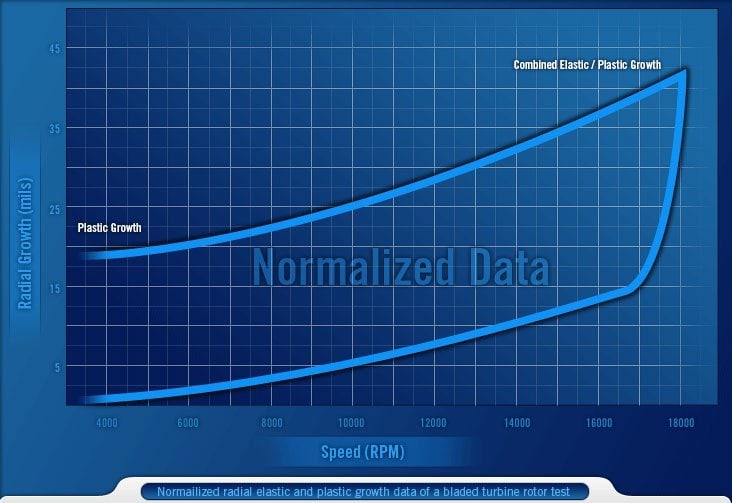

Growth Measurement at Speed

An understanding of a turbine component under centrifugal loading and at realistic temperature is critical to the design process for optimizing performance and life. To address this need, Test Devices has developed methods to measure elastic and plastic radial growth of components in real-time during a spin test. Measurement of elastic/plastic radial growth can be made as the speed is increased right up to the point of failure (bursting). Measurements can also be made at temperature.

In-situ growth measurement is especially helpful in understanding the point (speed) at which plasticity occurs. Growth of disks or blades in an actual engine cannot be tolerated so this “rotational yield point” must be engineered to occur at speeds greater than the maximum operating speed of the engine.

Many engine manufacturers actually include rotational yielding as a production operation. This is generally known as Production Pre-spin. It is used to “homogenized” the varying residual stresses that occur in turbine disks during forging and subsequent heat treating and is performed just prior to the final machining of the disks. The pre-spin operation assures that no growth will occur during engine operation regardless of its fabrication history. Test Devices performs a large volume of production pre-spinning for many engine OEM’s.

Predictive models of elastic and plastic growth in actual components can be inaccurate due to variation in the fabrication process – especially for disks with complex geometries and features. In-situ growth measurement can be helpful in validating computer models for new and advanced aerospace alloys or when material performance of an existing component does not match the predictive models.

Radial growth testing is beneficial for any component which experiences growth, elastic or plastic, during normal operation at high speed. Below is a list of components for which growth is commonly measured at speed.

| Jet Engine Rotors | Alloy Flywheels | Industrial Gas Turbine Rotors |

| Composite Flywheels | High-Speed Electric Motors | Material Characterization |

Download Our Spin Testing Ebook

Traditional Growth Measurement

Mechanical measurements (e.g. calipers) are traditionally employed to measure the plastic radial growth component only. The method employs an iterative approach whereby components are repeatedly accelerated to predetermined speeds, decelerated to 0 rpm, and then measured. This approach is time consuming and relies heavily on predicted growth curves not actual growth data.

Procedure

Test Devices’ typically uses eddy current or optical laser probes to measure elastic/plastic radial growth of high-speed rotating components. Multiple sensing methods gives us the flexibility to choose the optimal mix of probe types in order to measure growth at various locations of components that are made of more than one material type Components that are all one homogeneous material often also require multiple sensing elements as well in order to record growth along variations in geometry or interruptions in surfaces along the part.

For instance, many electric motor/generator rotor assemblies include not only stacks of laminations but also retaining assemblies of differing materials designed to provide axial load to the laminate stacks during operation. Thus, it is important to not only measure the growth of the laminate stacks, but also the performance of the retaining assemblies.

The sensors are individually calibrated and aligned with the rotor surface to ensure accurate measurements. Sensor to rotor gap is typically established based on customer supplied predictive growth. Once the probes are installed, the rotor is accelerated to predefined speeds to initiate growth. Measurements are taken not only during acceleration but also during deceleration to determine the extent of permanent deformation.

An important point to remember is that the measurements recorded by the proximity sensors include vibration occurring in the rotating assembly. Therefore, Test Devices has developed a method to remove the effect of the vibration from the recorded data in order to avoid misrepresenting the growth measurements.

Download Our Spin Testing Ebook

Data Acquistion and Reporting

Test Devices uses an on-line high-speed data acquisition system to record all test parameters throughout the duration of radial growth tests. All test data are included in the final report together with all other project paperwork, including growth measurement data, certificates of conformance, balance, heat calibrations, and tooling material certificates. Test data is also archived at Test Devices for the customer’s future reference.